Industrial efficiency is essential for a sustainable manufacturing plant. However, when systems become outdated, productivity drops and costs rise. This was exactly the challenge faced by a major manufacturing plant in Northern Ontario. The management team realized a complete overhaul was necessary, but they didn’t know where to begin. That’s where our teams at the Patrick Group of Companies stepped in to help.

Identifying the Challenge in the Manufacturing Plant

After more than 20 years in operation, the plant’s systems, once state-of-the-art, had become obsolete. As a result, inefficient HVAC, aging mechanical infrastructure, and frequent breakdowns slowed productivity and increased maintenance costs. To stay competitive, the plant needed a full transformation.

Our Integrated Solution

To address these issues, we united the expertise of Patrick Mechanical Ltd. (PML), Patrick Sprack Ltd. (PSL), and S2 Metal Fabricators. Working together, we delivered a seamless upgrade:

- Patrick Mechanical Ltd.: First, we assessed and redesigned the plant’s mechanical systems. By implementing modern technologies, we significantly improved efficiency.

- PSL Patrick Sprack Ltd.: Next, we upgraded heating, ventilation, and air conditioning with advanced HVAC solutions. This not only reduced energy use but also improved air quality.

- S2 Metal Fabricators: Meanwhile, S2 provided precision steel fabrication, ensuring secure integration of new systems into the existing infrastructure.

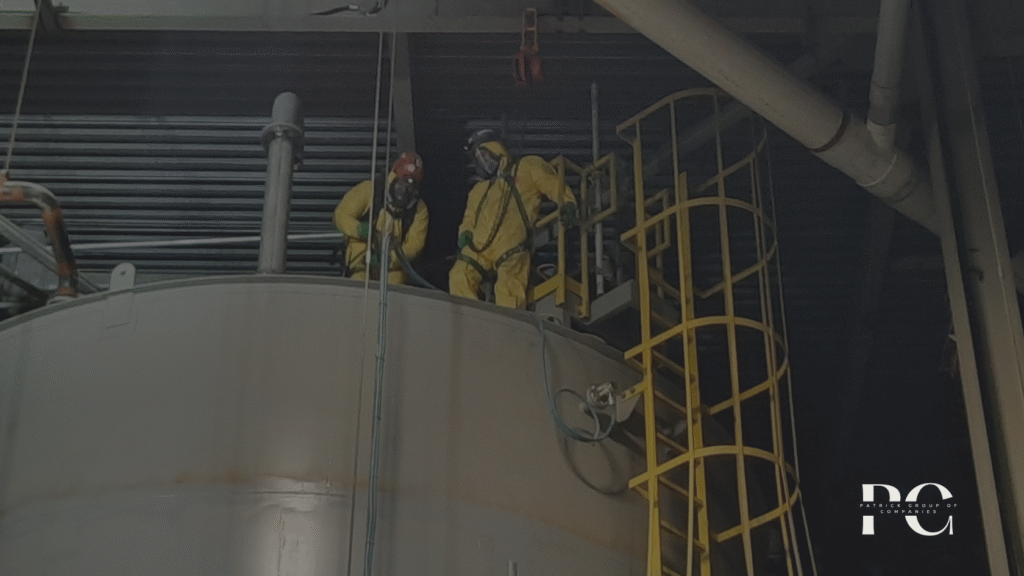

The Transformation Process

To minimize disruption, we used a careful, phased approach:

- Assessment and Planning: Initially, our teams inspected all systems and created a detailed action plan.

- Design and Fabrication: Then, PML designed new mechanical systems, PSL developed HVAC upgrades, and S2 fabricated structural supports. This ensured compatibility and optimization across all systems.

- Implementation: During installation, each company worked together for a smooth and efficient process.

- Testing and Optimization: Finally, we tested all systems thoroughly and optimized performance, resulting in a remarkable 30% productivity boost.

Results That Matter

Thanks to our efforts, the plant now benefits from reliable mechanical systems, energy-efficient HVAC, and durable structural support. As a result, downtime has dropped, energy costs are lower, and the work environment is safer and more comfortable. Overall, productivity increased by 30%, positioning the plant to meet market demands and continue growing.

Collaborative Excellence

In conclusion, this project highlights our ability to deliver integrated solutions for complex industrial challenges. By combining the strengths of PML, PSL, and S2 Metal Fabricators, we not only solved immediate issues but also set the plant up for long-term success.

Ultimately, our collaborative approach is key to transforming industrial efficiency in Northern Ontario.